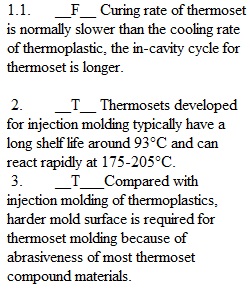

Q Q1. True or False Questions (put “T” or “F” below for each questions, each 10 pts) 1.Curing rate of thermoset is normally slower than the cooling rate of thermoplastic, the in-cavity cycle for thermoset is longer. 2.Thermosets developed for injection molding typically have a long shelf life around 93°C and can react rapidly at 175-205°C. 3.Compared with injection molding of thermoplastics, harder mold surface is required for thermoset molding because of abrasiveness of most thermoset compound materials. 4.Gates are typically smaller for thermosets than for thermoplastics in injection molding. 5.___ Normally, Injection molding of thermosets is a chemical process, while injection molding of thermoplastics is a physical process. 6.Due to its curing reaction, the viscosity – temperature relationship of thermosets display a “U”-shape curve.

View Related Questions